The final step in treating wastewater before releasing it into the natural environment is to kill any harmful microorganisms (e.g. viruses, bacteria) in it. This is called disinfection, and chlorine gas is a very effective disinfecting agent. However, just as it is not good to mix too little chlorine in the outgoing water (effluent) because we might not disinfect the water thoroughly enough, there is also danger of injecting too much chlorine in the effluent because then we might begin poisoning animals and beneficial microorganisms in the natural environment.

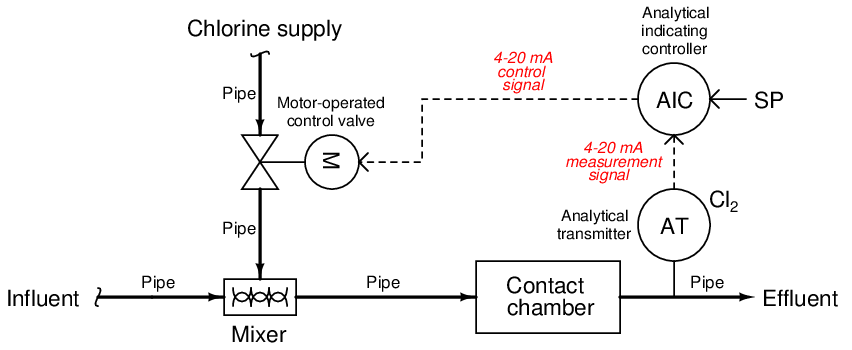

To ensure the right amount of chlorine injection, we must use a dissolved chlorine analyzer to measure the chlorine concentration in the effluent, and use a controller to automatically adjust the chlorine control valve to inject the right amount of chlorine at all times. The following P&ID (Process and Instrument Diagram) shows how such a control system might look:

Chlorine gas coming through the control valve mixes with the incoming water (influent), then has time to disinfect in the contact chamber before exiting out to the environment.

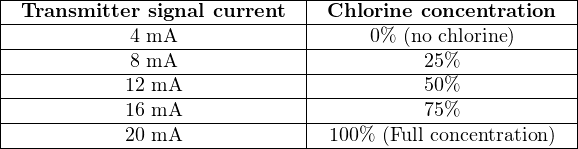

The transmitter is labeled “AT” (Analytical Transmitter) because its function is to analyze the concentration of chlorine dissolved in the water and transmit this information to the control system. The “Cl2” (chemical notation for a chlorine molecule) written near the transmitter bubble declares this to be a chlorine analyzer. The dashed line coming out of the transmitter tells us the signal is electric in nature, not pneumatic as was the case in the previous (boiler control system) example. The most common and likely standard for electronic signaling in industry is 4 to 20 milliamps DC, which represents chlorine concentration in much the same way as the 3 to 15 PSI pneumatic signal standard represented steam drum water level in the boiler:

The controller is labeled “AIC” because it is an Analytical Indicating Controller. Controllers are always designated by the process variable they are charged with controlling, in this case the chlorine analysis of the effluent. “Indicating” means there is some form of display that a human operator or technician can read showing the chlorine concentration. “SP” refers to the setpoint value entered by the operator, which the controller tries to maintain by adjusting the position of the chlorine injection valve.

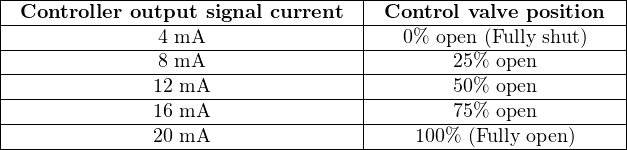

A dashed line going from the controller to the valve indicates another electronic signal: a 4 to 20 mA direct current signal again. Just as with the 3 to 15 PSI pneumatic signal standard in the pneumatic boiler control system, the amount of electric current in this signal path directly relates to a certain valve position:

Note: it is possible, and in some cases even preferable, to have either a transmitter or a control valve that responds in reverse fashion to an instrument signal such as 3 to 15 PSI or 4 to 20 milliamps. For example, this valve could have been set up to be wide open at 4 mA and fully shut at 20 mA. The main point to recognize here is that both the process variable sensed by the transmitter and the position of the control valve are proportionately represented by analog signals.

Just as with the 3 to 15 PSI pneumatic signals used to represent water level and control valve position in the boiler seen previously, the two 4 to 20 milliamp current signals in this system represent two different variables in the system and therefore will not be equal to each other except by coincidence. A common misconception for people first learning about analog instrumentation signals is to assume the transmitter’s signal (“Process Variable”) must be identical in value to the control valve’s signal (“Manipulated Variable” or “Output”), but this is not true.

The letter “M” inside the control valve bubble tells us this is a motor-actuated valve. Instead of using compressed air pushing against a spring-loaded diaphragm as was the case in the boiler control system, this valve is actuated by an electric motor turning a gear-reduction mechanism. The gear reduction mechanism allows slow motion of the control valve stem even though the motor spins at a fast rate. A special electronic control circuit inside the valve actuator modulates electric power to the electric motor in order to ensure the valve position accurately matches the signal sent by the controller. In effect, this is another control system in itself, controlling valve position according to a “setpoint” signal sent by another device (in this case, the AIT controller which is telling the valve what position to go to).