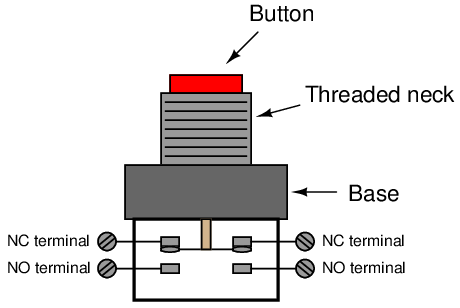

A hand switch is exactly what the name implies: an electrical switch actuated by a person’s hand motion. These may take the form of toggle, pushbutton, rotary, pull-chain, etc. A common form of industrial pushbutton switch looks something like this:

The threaded neck inserts through a hole cut into a metal or plastic panel, with a matching nut to hold it in place. Thus, the button faces the human operator(s) while the switch contacts reside on the other side of the panel.

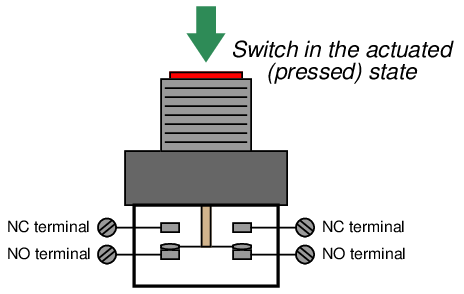

When pressed, the downward motion of the actuator breaks the electrical bridge between the two NC contacts, forming a new bridge between the NO contacts:

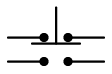

The schematic diagram symbol for this type of switch looks much like the real thing, with the normally-closed contact set on top and the normally-open contact set below:

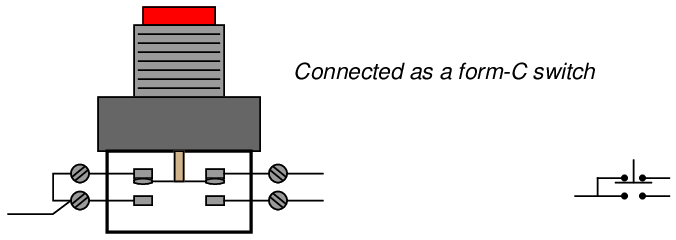

Connecting two of the terminals together makes this form of switch electrically identical to a Form C:

This switch contact arrangement is sometimes referred to as a form-C contact set, since it incorporates both a form-A contact (normally-open) as well as a form-B contact (normally-closed).

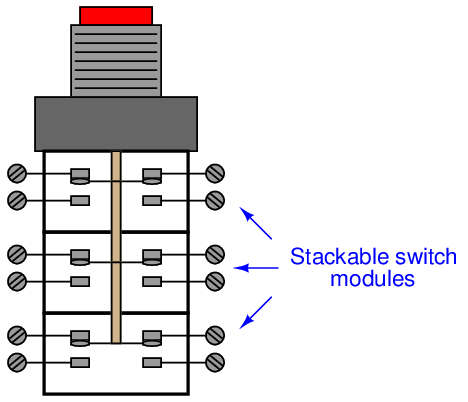

Most industrial hand switches are available in modular form, where sets of switch contact blocks may be “stacked” together to be actuated by the same pushbutton or rotary knob. This allows an almost unlimited number of switch contacts to be simultaneously actuated by a single actuating mechanism. Different actuator types such as pushbuttons, rotary selectors, knobs, and keyswitches may also be interchanged with contact modules for maximum flexibility: