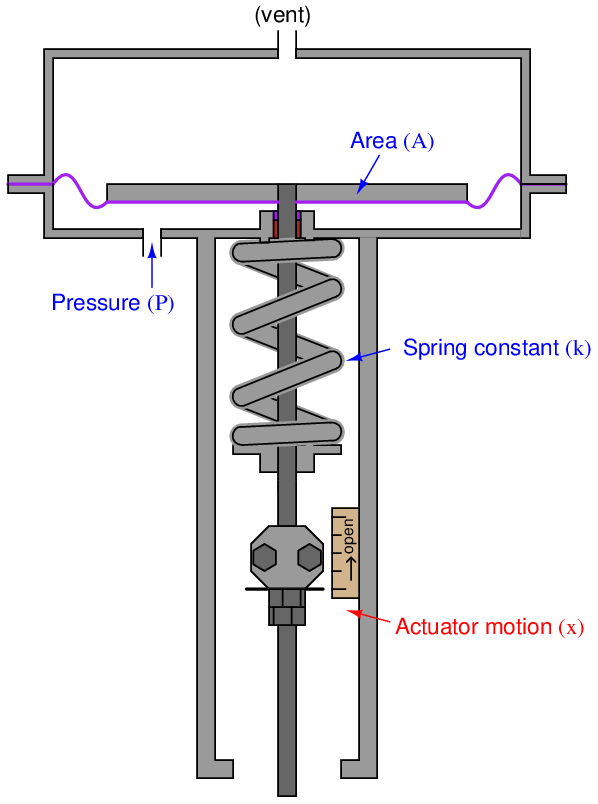

Valve actuators provide force to move control valve trim. For precise positioning of a control valve, there must be a calibrated relationship between applied force and valve position. Most pneumatic actuators exploit Hooke’s Law to translate applied air pressure to valve stem position.

Where,

F = Force applied to spring in newtons (metric) or pounds (British)

k = Constant of elasticity, or “spring constant” in newtons per meter (metric) or pounds per foot (British)

x = Displacement of spring in meters (metric) or feet (British)

Hooke’s Law is a linear function, which means that spring motion will be linearly related to applied force from the actuator element (piston or diaphragm). Since the working area of a piston or diaphragm is constant, the relationship between actuating fluid pressure and force will be a simple proportion (F = PA). By algebraic substitution, we may alter Hooke’s Law to include pressure and area:

Solving for spring compression as a function of pressure, area, and spring constant:

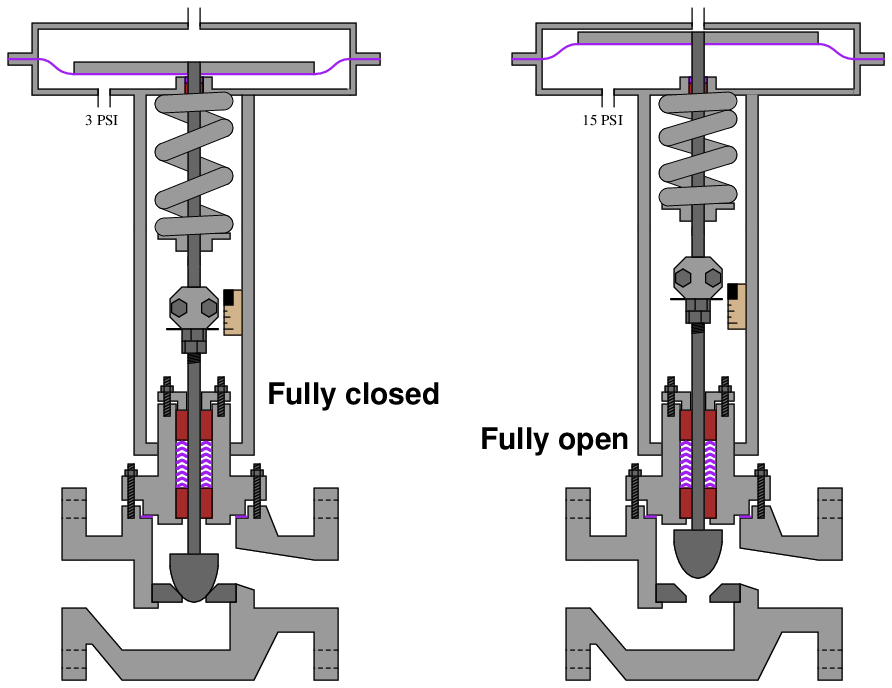

When a control valve is assembled from an actuator and a valve body, the two mechanisms must be coupled together in such a way that the valve moves between its fully closed and fully open positions with an expected range of air pressures. A common standard for pneumatic control valve actuators is 3 to 15 PSI13 .

There are really only two mechanical adjustments that need to be made when coupling a pneumatic diaphragm actuator to a sliding-stem valve: the stem connector and the spring adjuster. The stem connector mechanically joins the sliding stems of both actuator and valve body so they move together as one stem. This connector must be adjusted so neither the actuator nor the valve trim prevents full travel of the valve trim:

Note how the plug rests fully on the seat when the valve is closed, and how the travel indicator indicates fully open at the point where the actuator diaphragm nears its fully upward travel limit. This is how things should be when the stem connector is properly adjusted.

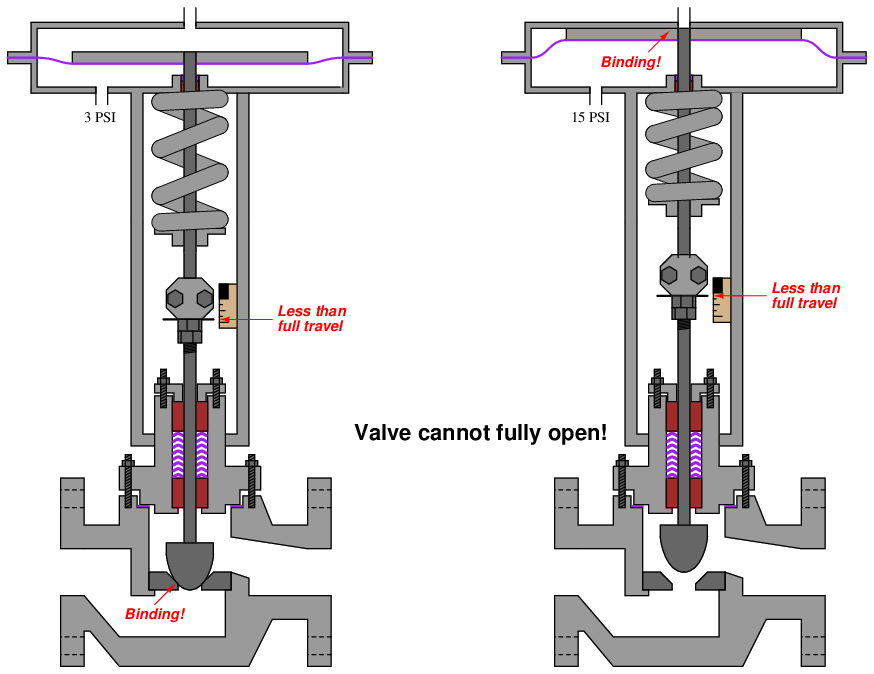

If the stem connector is set with the actuator and valve stems spaced too far apart (i.e. the total stem length is too long), the actuator diaphragm will bind travel at the upper end and the valve plug will bind travel at the lower end. The result is a valve that cannot ever fully open:

A control valve improperly adjusted in this manner will never achieve full-flow capacity, which may have an adverse impact on control system performance.

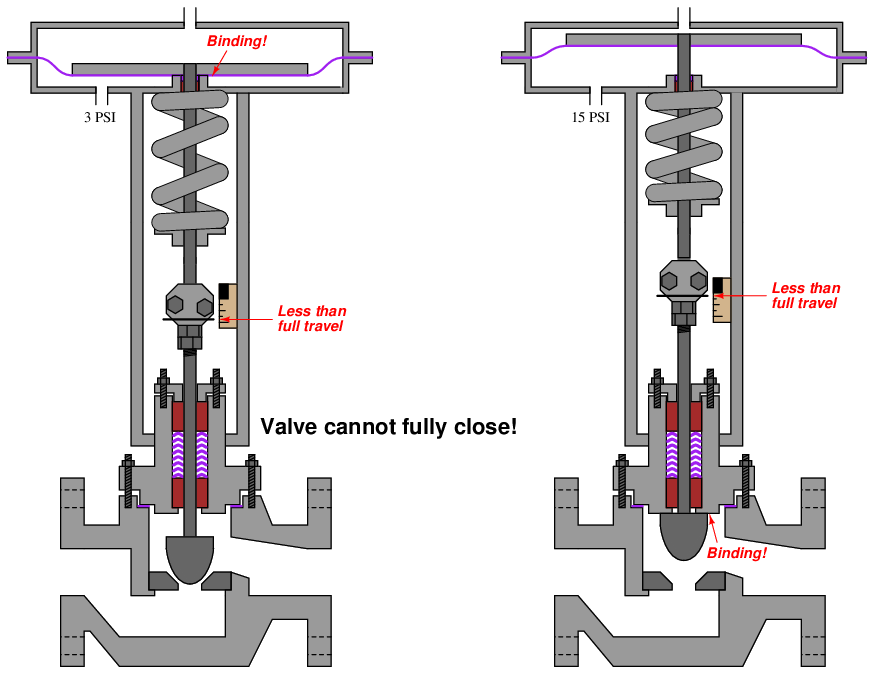

If the stem connector is set with the actuator and valve stems too closely coupled (i.e. the total stem length is too short), the actuator diaphragm will bind travel at the lower end and the valve plug will bind travel at the upper end. The result is a valve that cannot ever fully close:

This is a very dangerous condition: a control valve that lacks the ability to fully shut off. The process in which this valve is installed may be placed in jeopardy if the valve lacks the ability to stop the flow of fluid through it!

Once the stem length has been properly set by adjusting the stem connector, the spring adjuster must be set for the proper bench set pressure. This is the pneumatic signal pressure required to lift the plug off the seat. For an air-to-open control valve with a 3 to 15 PSI signal range, the “bench set” pressure would be 3 PSI.

Bench set is a very important parameter for a control valve because it establishes the seating force (seat load) of the plug against the seat when the valve is fully closed. Proper seating pressure is critical for tight shut-off, which carries safety implications in some process services. Consult the manufacturer’s instructions when adjusting the bench set pressure for any sliding-stem control valve. These instructions will typically guide you through both the stem connector and the spring adjuster procedures, to ensure both parameters are correctly set.