Electrical power is a commodity in the modern world, bought and sold on the open market like any other. Thus, it is important to be able to measure and control electricity, not only for reasons of efficiency but also for sale, taxation, safety, equipment protection, and reliability of service.

As with any other quantity we wish to measure and control, the systems designed for these purposes may be divided into three general categories: sensors to measure, final control elements to exert influence, and controllers to make the necessary control decisions automatically. This chapter will discuss all three of these categories as they relate to measurement and protection subsystems found in modern electrical power grids.

This chapter cannot in any way do justice to the scope and complexity of electrical power grids. What it aims to do, however, is focus on the monitoring and protective functions subsystems essential to any functional power grid – the instrumentation within an electrical power grid, as it were – touching on the function of various pieces of electrical equipment as necessary to understand the purpose and application of those monitoring and protective subsystems.

25.1 Introduction to power system automation

Those familiar with industrial instrumentation will find much within the electric power industry remarkably familiar in concept. In industrial instrumentation we apply principles of physics, electricity, and chemistry to the measurement and automation of a wide range of “processes”. In the electric power industry the main “process” is the flow of electrical energy across long distances, but within that main process are a multitude of smaller processes with their own sensors, final control elements, and computation/control devices.

Within each of those smaller processes in a large electrical power system there exist automatic monitoring and control systems very similar to industrial process controls. A general block diagram showing the essential components of a feedback control system (used elsewhere in this book) applies to electrical power system automation as well:

Measurement devices in an electrical power system usually take the form of instrument transformers designed to represent high voltage and high current quantities as smaller, proportionate electrical signals. Controllers take the form of protective relays and other control systems designed to display and record the measured quantities, as well as take automatic control action. Final control is generally realized in the form of circuit breakers designed to redirect power flow and/or isolate sections of the power system.

Modern electrical power automation systems, like industrial automation, also employ sophisticated digital communication subsystems to exchange critical data such as power flow and fault diagnosis across wide regions.

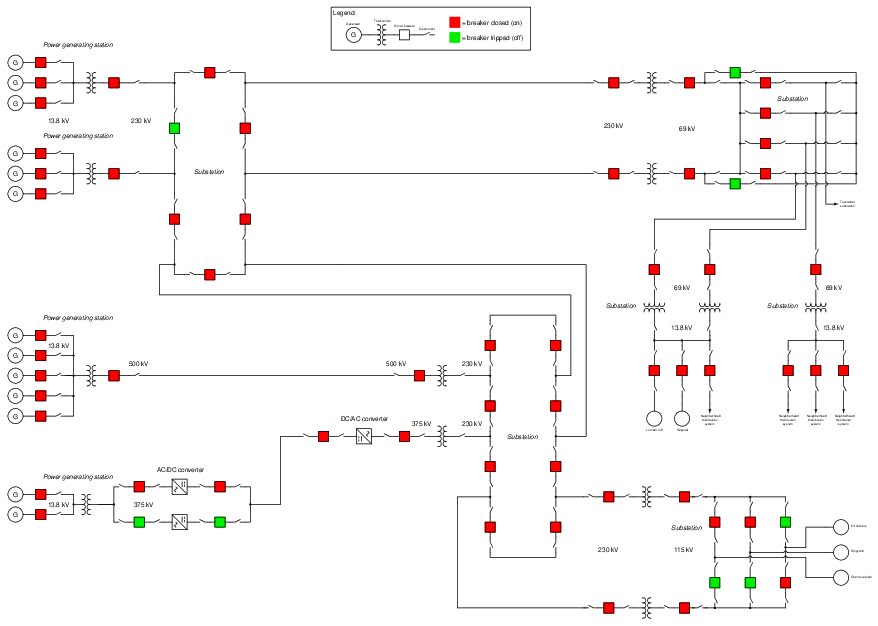

Let us examine electric power substations as an example of automation. A “substation” is to an electrical power system what an intersection is to a system of highways and streets: a place where multiple paths intersect and flows are directed to their intended destinations. Just as road maps are used to graphically represent roads and intersections, single-line diagrams1 are used to represent power lines and substation components. An example of a single-line diagram showing multiple substations appears here:

Electrical generators appear as circles with the letter “G” inside. Loads also appear as circles, but labeled uniquely. Circuit breakers (used to interrupt the flow of power during full-load and fault conditions) appear as squares, shown here with color-coded states2 . Disconnect switches (used to isolate components from power during maintenance operations) appear as standard schematic switch symbols: a line broken by a diagonal line segment. Short line segments joining circuit breakers and disconnects with other devices in each station represent busses, which are sets of rigid metal conductors suspended by insulators. Longer lines connecting stations to each other represent transmission or distribution power lines. Transformers, used to step voltage up and current down for efficient long-distance transmission, or vice-versa for distribution and end-use, appear as standard schematic winding symbols. All these devices appear on single-line diagrams with single lines showing the route for power into and/or out of the device, rather than showing all electrical conductors connecting with the actual devices. This simplification is similar to the way road maps show streets and highways as single lines but generally do not show the number of lanes within each road.

Within each of these substations you can see circuit breakers and disconnect switches used to route the flow of electricity from sources to loads. These devices are analogous to control valves and block valves used to control fluid motion in industrial processes. Each circuit breaker, as a “final control element” in an automated system, may be commanded to open (trip) and/or close either by human action or by automatic action through special controllers called protective relays designed to protect the power system against damage caused by faults such as downed power lines, lightning strikes, and insulator breakdown. These protective relays sense voltage and current conditions through instrument transformers stepping high voltage down to safe sensing levels (Potential Transformers, or PTs) and stepping line current down to safe levels (Current Transformers, or CTs).

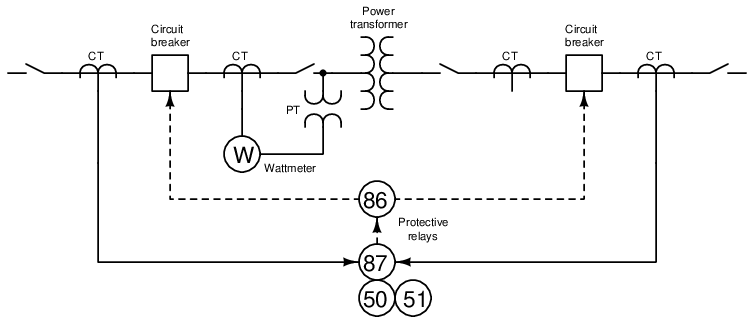

An example of a single-line diagram showing such an automated protection system for one of the power transformers in this system appears here:

Each protective relay function appears as a small circle enclosing a number, representing an industry-standardized code for that protective function (e.g. 50 = instantaneous overcurrent, 51 = time overcurrent, 86 = lockout, 87 = differential current). Solid lines show power and analog signal wiring, while dashed lines show control (relay output) wiring which are typically discrete (on/off) signals. In this particular case, any condition of overcurrent or current imbalance for this transformer causes the lockout relay (86) to trip, which in turn commands both line and load circuit breakers to trip, isolating the power transformer and thereby protecting it from harm. A single potential transformer array (PT) steps down the high line voltage to a safe level (typically 120 volts nominal) for the wattmeter to read. A set of current transformers (CTs) step line current down to safe levels (typically 5 amps at full load) for the wattmeter and protective relays to read. As you can see, the disconnect switches have no connection to the automated system because they are manually-controlled devices, analogous to manual block valves flanking an automatic control valve in a process pipe.

Now that we know the functions of instrument transformers, protective relays, circuit breakers, and disconnect switches, we may examine some photographs of these power system components. First, we will examine some potential transformers (PTs), sometimes referred to as voltage transformers (VTs). The left-hand photograph shows a set of three PTs, each one used to sense phase-to-ground voltage in a 115 kV 3-phase power bus within a substation. The right-hand photograph shows a single PT sensing phase-to-phase voltage (i.e. line voltage) for a 13.8 kV bus within a substation:

Each of these PTs step high voltage down to a nominal value of 120 volts for direct meter indication and/or protective relay input signals. This is analogous to the industrial instrumentation signal standard of 4-20 mA representing such things as pressure, flow, and temperature: a relatively small electrical signal is used as a representation of some other real-world measurement. As the power system voltage rises as falls, these PTs’ voltage output signals will rise and fall proportionate to the turns ratio3 of each transformer.

Next we will examine some current transformers (CTs). The left-hand photograph shows a current transformer with a 400:5 amp ratio, which means a line current of 400 amps AC passing through the horizontal metal bar will induce a secondary winding current of 5 amps AC available at the screw terminals on top of this CT. The middle photograph is another style of CT, often called a “donut” or “window” CT because it has a large hole in the center through which the power conductor is routed (as a single “turn” primary winding). The right-hand photograph shows a set of CTs used to measure current in a 500 kV substation, the CT being located at the very top inside the box, while a long insulator supports the CT and holds it several feet above ground level for safety (since 500 kilo-volts can “jump” a fair distance through air and therefore must be separated from the earth):

All of these CTs output a nominal current of 5 amps AC at full load rating, which is a common CT signal standard within the electrical power industry, like 120 volts is for PT output signals. As line current rises and falls, these CTs’ signals will proportionately rise and fall according to the turns ratio4 of each CT. These 0 to 5 amp AC signals are wired to measuring and/or protection instruments located in the substation control building.

Together, PTs and CTs constitute the primary sensing elements of electrical power measurement, control, and protection systems. One of the tasks of metering and protection technicians in the electric power industry is to periodically check the accuracy and performance of these instrument transformers, just as an industrial instrument technician periodically checks the calibration of process sensing elements and transmitters.

Next we will examine some of the panel-mounted instruments receiving signals from PTs and CTs. First are simple meters, designed to display system measurements to human operators. These instruments are labeled with high ranges despite the fact that their actual driving signals are relatively small (e.g. 0 to 120 volts for voltage instruments and 0 to 5 amps for current instruments). This next photograph shows a portion of an analog control panel with several meters registering voltage, current, and power factor5 values for a substation bus. Several indicating lamps (red and green) show the statuses of various circuit breakers in the substation yard, with L-handle control switches providing remote trip/close operation of circuit breakers and red plastic lines representing the single-line diagram of the substation:

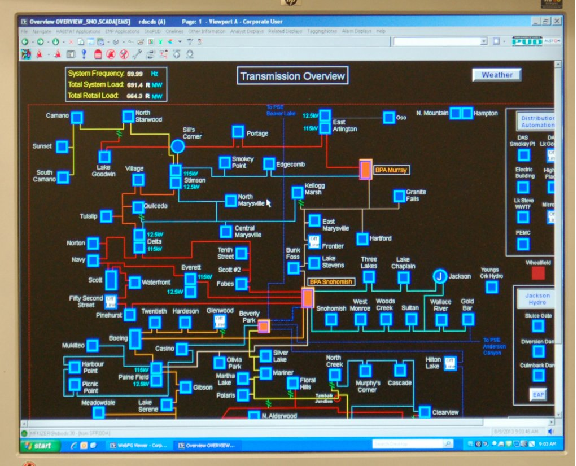

Modern SCADA (Supervisory Control And Data Acquisition) hardware designed for power systems also input PT and CT signals, displaying those values on computer monitors instead of analog meter movements. In addition to analog voltage and current signals, SCADA systems also input discrete signals from circuit breaker auxiliary contacts, disconnect switch status contacts, pressure switches, and other on/off sensing devices located near the high-voltage power conductors. This provides operators with remote viewing of device status, which is then displayed as different colors (red or green) on a graphic single-line diagram of the power system.

The following photograph shows a SCADA display screen of a large public utility power grid. The scale of this particular display is such that individual circuit breakers are not represented, showing entire substations as single colored squares. However, more detailed diagrams are viewable by selecting a particular substation on this screen, these detailed displays showing individual circuit breakers and other associated equipment within that substation:

SCADA systems utilize a variety of telecommunication pathways to distribute power system data over long distances, including microwave (radio), optical fiber, leased telephone lines, and sometimes even high-frequency AC signals superimposed6 on power line conductors.

Protective relays have been described as the “silent sentinels” of electric power systems, quietly monitoring voltage and/or current conditions, ready to spring into action to protect the system against damage from faults. These automatic control devices have existed in one form or another for over a century, beginning with crude electromechanical designs and now culminating in state-of-the-art microprocessor-based computing machines. Relay functions are commonly designated by numerical codes standardized by ANSI, some of which will be listed in this section.

A series of electromechanical protective relays appears in the following photographs, taken at a large substation. The left-hand photograph shows a pair of distance relays (ANSI code 21) designed to sense the electrical impedance7 of a long power line and its load, tripping the circuit breaker(s) supplying power to that line if a fault reduces the impedance to a value equal to or less than that of the line itself. The middle photograph shows a set of transformer differential current relays (ANSI code 87) designed to compare the amount of current in the primary and secondary windings of a transformer, tripping circuit breakers on both sides of the transformer in the event a transformer fault is detected (i.e. if the amount of current exiting the transformer does not proportionately match the amount of current entering it). The right-hand photograph shows a set of overpressure relays (ANSI code 63) designed to trip circuit breakers feeding power to a device if the pressure inside that device rises to unacceptable levels:

A routine task for relay technicians working on electromechanical relays is periodic recalibration of these devices. Since they contain potentiometers, magnets, inductive coils, and moving parts they are susceptible to calibration drift just like any other analog electronic or mechanical device.

Modern digital electronic protective relays are also panel-mounted, but of course contain no moving parts and are much more capable in terms of their ability to discriminate between normal operating conditions and faulted conditions meriting the tripping of circuit breakers. The following photographs show some examples of these devices. The left-hand photograph shows a transformer protection relay, incorporating the differential current (ANSI code 87) protection of the previous electromechanical relay plus a number of other features including instantaneous and time-overcurrent functions. The right-hand photograph shows a pair of digital relays, the upper one providing instantaneous overcurrent (ANSI code 50) plus time-overcurrent (ANSI code 51) plus circuit breaker reclosing (ANSI code 79) functionality, tripping the circuit breaker in the event of excessive current8 , and then re-closing that same circuit breaker a short moment after to check if the fault has cleared. The right-hand photograph shows a directional overcurrent relay (ANSI code 67) designed to sense excessive line current in one particular direction9 along the line, tripping the circuit breaker(s) feeding power to that line is a fault is detected:

One of the benefits of digital protective relays is their remarkable stability compared to electromechanical relays, being virtually immune to calibration drift. This translates to less routine maintenance for relay technicians.

Not only do modern protective relays perform their basic system protection functions, but they also record data for later retrieval and analysis by relay technicians and protection engineers. These relays, being microprocessor based, may also be interconnected using high-speed data networks to exchange data with each other as part of certain protection strategies. These new capabilities, coupled with the need to maintain accurate archives of digital relay configuration files, means the job of the relay technician has evolved: there is less routine calibration work, but more routine record-keeping and high-level diagnostic work.

Finally, we have the final control elements of the electric power industry: circuit breakers and disconnects. These two types of devices are common in that they both serve to connect and disconnect portions of a power system. They differ in their ability to interrupt current: circuit breakers are built with very rugged electrical contacts capable of safely and reliably interrupting huge magnitudes of electric current (including currents arising from short-circuit faults in the power system), whereas disconnects are switches that cannot make or break such large currents, and are intended to be operated only when the series-connected circuit breaker is open (tripped).

The following photographs show sets of three-phase 115 kV disconnects, the left-hand photograph showing a set in the closed position and the right-hand photograph showing a set in the open position:

As you can see, a high-voltage disconnect is nothing more than an open-air knife switch. Some are manually operated (by a lever or a hand crank) while others use an electric motor for remote operation by a SCADA system or by an operator in a substation control room.

Medium-voltage and high-voltage circuit breakers come in a variety of shapes and sizes. Perhaps the most significant difference between them is the method(s) employed to extinguish the electric arc formed when the contacts separate to interrupt line current. Some circuit breakers have their contacts immersed in a tank of dielectric oil, while others use contacts sealed inside of vacuum chambers (where there is no gas at all to ionize and create an arc), or enclose their contacts in chambers filled with a special dielectric gas such as sulfur hexafluoride (SF6), or use high-pressure jets of air to “blow out” the arc.

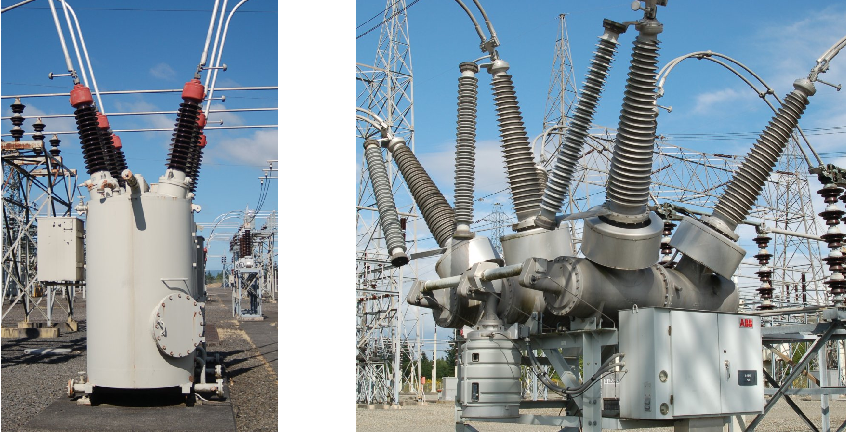

The photograph on the left shows a legacy oil-tank circuit breaker in a 115 kV substation yard, consisting of three separate tanks containing contacts to interrupt one phase each. All three contacts operate simultaneously by the same mechanism. The right-hand photograph shows a more modern circuit breaker design, this one in a 250 kV substation yard, enclosing its three contact sets in pressurized SF6 gas:

Safe and effective interruption of electric current at these elevated potentials demands quick contact action, and this is possible only with some form of stored-energy mechanism inside the circuit breaker. Some large circuit breakers use reservoirs filled with compressed air as the actuating medium, the reservoir maintained in a state of high pressure by an electric air compressor. Other circuit breakers use mechanical springs pre-charged by an electric motor and gear mechanism10 . In all designs, though, the energy required to quickly close and open (trip) the circuit breaker contacts is provided by some energy-storage mechanism, that energy released on command by electric solenoid coils which may be remotely operated by human action and/or by protective relays.

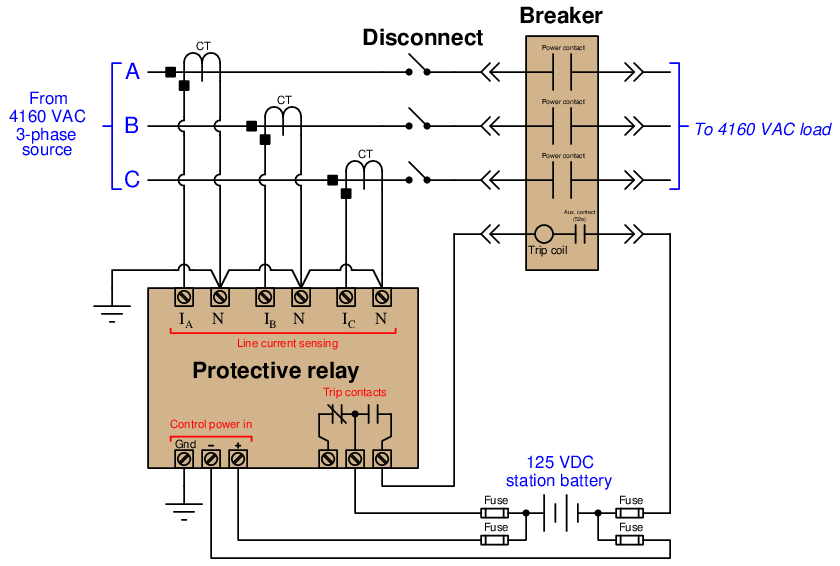

Putting all these devices together and representing them in schematic form, we see the following example whereby a protective relay senses line current and issues a “trip” command to the medium-voltage (4160 volt AC) circuit breaker in the event of an overcurrent (fault) condition:

125 volt DC “station” power is used in this particular system for high reliability, ensuring the protective system will still be able to function even if an interruption occurs in AC power to the station. This 125 volt battery bank is maintained in a continuous state of charge by an AC-DC battery charger fed from the AC power source (not shown).

In summary, electric power systems employ automation to measure power conditions and take protective action when needed in the event of major line or device faults. These automated systems resemble industrial process control and safety systems in their three-part division (sensing, control, and final action) as well as in their graphical representation, calibration, and other maintenance.